Parallel port TFT LCD screens are widely used in embedded systems, industrial control panels, and consumer electronics, leveraging parallel communication to transmit data between the display module and the host controller. Unlike serial interfaces that send data bit by bit, parallel ports transfer multiple bits simultaneously (typically 8 or 16 bits), enabling faster data transmission—critical for high-resolution TFT LCDs requiring rapid screen updates. This makes them ideal for applications such as medical monitors, where real-time data visualization is essential, or gaming devices needing smooth graphics rendering.

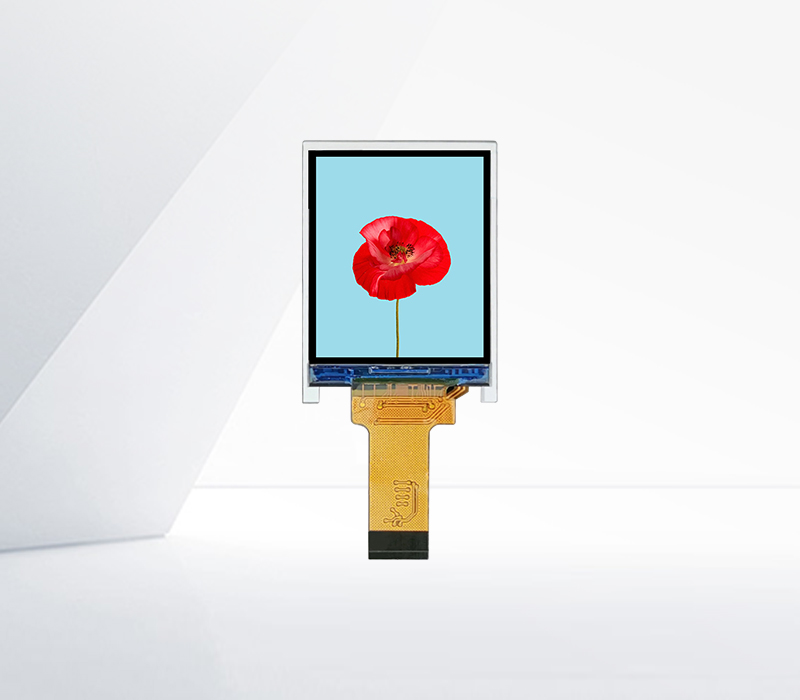

A parallel port TFT LCD module consists of the TFT panel, a driver IC, and a parallel interface circuit. The parallel interface uses control signals like RS (Register Select), WR (Write), RD (Read), and CS (Chip Select) to manage data flow, ensuring the host correctly communicates commands (e.g., setting display orientation) and pixel data to the driver IC. The driver IC converts the parallel data into signals that control the TFT’s liquid crystal molecules, adjusting light transmission to form images.

One key advantage of parallel ports is their simplicity in integration with microcontrollers (MCUs) and processors that lack high-speed serial interfaces. They also support older hardware architectures, making them a cost-effective choice for legacy systems. However, parallel interfaces require more pins (e.g., 16 data lines plus control signals), increasing PCB complexity and limiting their use in ultra-compact devices. Modern designs often balance this by offering configurable interfaces, allowing users to switch between parallel and serial modes based on application needs. With advancements in TFT technology, parallel port displays now support high resolutions (up to 800x600 pixels), wide viewing angles, and vibrant color reproduction, maintaining their relevance in diverse industrial and consumer applications.